Warehouse Navigation

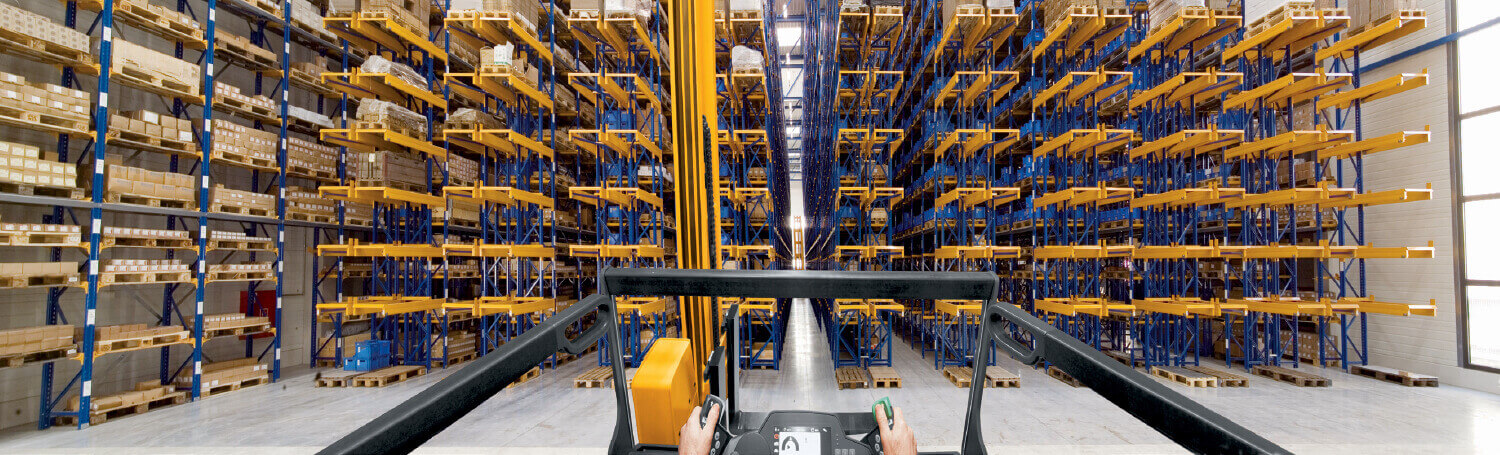

Warehouse Navigation helps you increase your productivity by up to 25% by improving order picking accuracy and reducing costs. Learn more below about how we can help you streamline your operation.

AUTOMATED GUIDED VEHICLE SYSTEMS (AGVS)

AUTOMATED GUIDED VEHICLE SYSTEMS (AGVS)

COUNTERBALANCED FORKLIFTS

COUNTERBALANCED FORKLIFTS

REACH TRUCKS

REACH TRUCKS

ORDER PICKERS

ORDER PICKERS

TURRET TRUCKS

TURRET TRUCKS

PALLET TRUCKS

PALLET TRUCKS

TOW TRACTORS

TOW TRACTORS

WALKIE STACKERS

WALKIE STACKERS

HAND PALLET TRUCK

HAND PALLET TRUCK

Warehouse Navigation helps you increase your productivity by up to 25% by improving order picking accuracy and reducing costs. Learn more below about how we can help you streamline your operation.

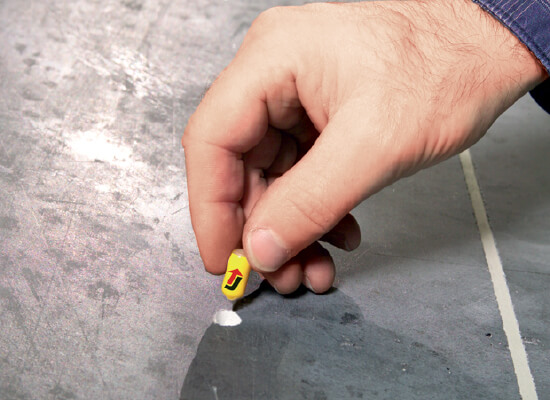

Warehouse Navigation uses RFID technology for a semi-automated approach to operating within your warehouse aisles. Transponders embedded in the floor precisely identify aisle locations and distances. Armed with this information, your lift truck takes the most efficient and productive path possible.

Warehouse Navigation offers a more flexible approach to automating your lift trucks. Gone are the days of restrictive lift truck commands, such as the slowing of trucks at the end of aisles with magnets. Now, operators can be directed automatically to locations within the racking system. If a rack row changes in the warehouse aisle, simply reprogram the transponders to adapt to the new locations. Warehouse Navigation also allows operators to effortlessly cease automation and take command of the lift truck for unprecedented control.

Order Pickers

EKS 412s/414s – Capacity: up to 3,000 lbs.

© 2023 Mitsubishi Logisnext Americas Inc. All registered trademarks and all logos are the property of their respective owners, including Jungheinrich®.

Let us help you find the right forklift for your business.